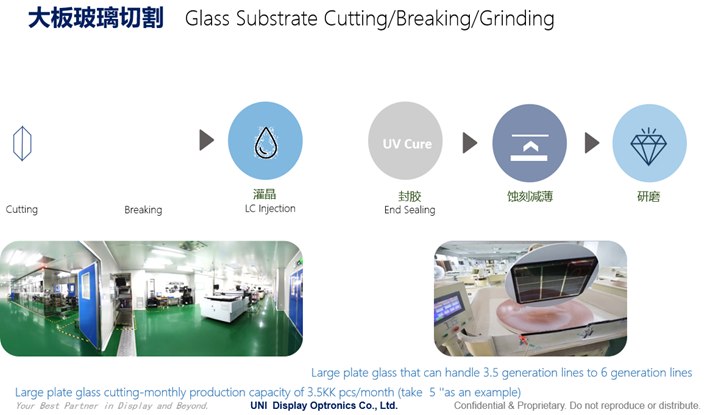

Glass Substrate Cutting/Breaking/Grinding

-

-

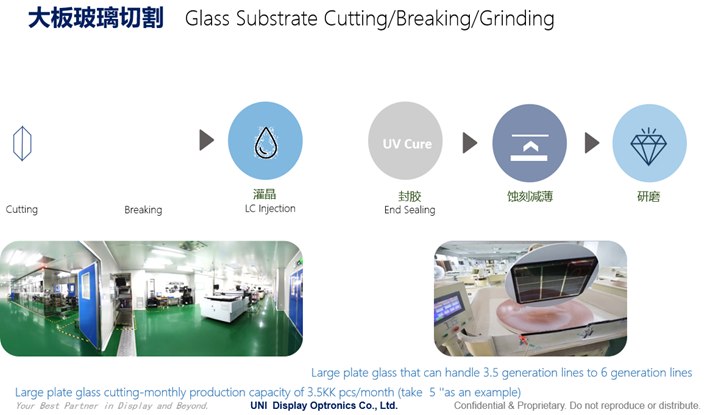

Glass Substrate Cutting/Breaking/Grinding

-

Brief Introduction of LCD Panel Cutting Process

-

1. Cutter wheel cutting

Common: using carbide grinding wheel scribing and cutting.

Disadvantages: will produce debris on the surface, need to increase the cleaning process.

2. Laser cutting

Laying: scanning the material with a high power laser beam, when the surface temperature of the material exceeds its softening temperature, the material begins to fuse, melt until vaporization.

Disadvantages: the generated temperature is extremely high, causing high thermal stress and residual stress will lead to micro cracks, the inner side of the cut surface will remain molten material, and it still needs to be cleaned after cutting.

Industry Information

Professional FPD/Touch Screen/Driving Board solution provider in Design/Manufacturing & Service

TFT LCM & Touch Panel Development and Manufacture, China lcd display manufacturer

UNI DISPLAY TECHNOLOGY LIMITED